From a German reader, Peter Schottler (email info [at] kulturata.de):

Fermented Gingerbread

Traditional German Christmas Cookies used to be made with fermented Lager Dough which was prepared around August and left to ferment until baking time in November / December.

This is a mostly forgotten art. This is very simple to make, with delicious results: Cookies with a very subtle, fine texture.

In August/September/October you prepare the basic dough without any spices/ dried fruit/nuts/leavening, which are all added later, when you bake the fermented gingerbread.

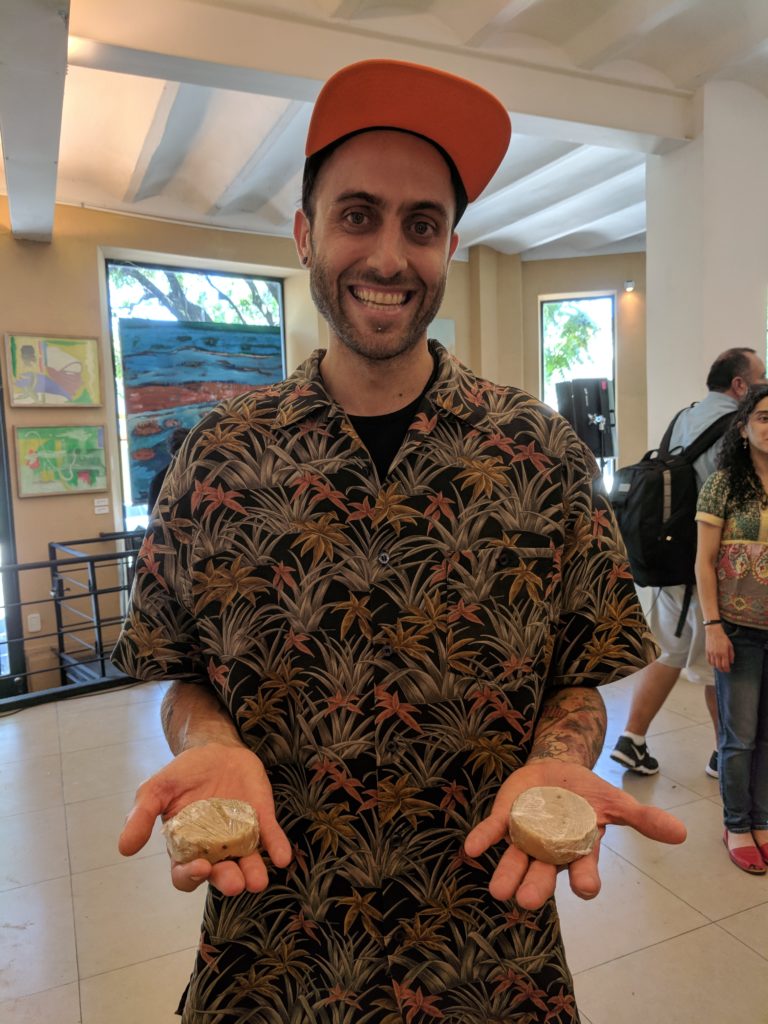

Traditionally, this kind of luxurious gingerbread cookie is baked on wafers. I use round wafers with a diameter of 70mm and I baked 530 gingerbread “Ellisen-Lebkuchen” this year – as they make a Christmas present you can’t easily buy, with an exquisite taste.

As I assume you want to start with a small quantity the first time, I’ll give you a small recipe.

For the Lager dough you need:

1 kg of organic blossom honey

1 kg of treacle (dark sugar syrup from beetroots)

2 kg of organic flour (I use spelt flour of a type between wholemeal and white)

That is all, if you want to rely on wild fermentation, which is the ‘old way’ to do it – that is to rely on the fungi, yeasts and bacteria from the organic flour and the organic blossom honey and to a lesser extent of the beetroot-syrup“ (Zuckerrübensirup) I use.

You take a large stainless steel pot with a lid, slowly warm the honey and the treacle to up to 37°C/99°F to make it easier to stir/knead in the flour. (This being the temperature in a bee hive, in the human body, and a temperature lactic acid bacteria like best – well, the ones I have spoken to…)

Once you have mixed the three components to form a dough, you put the lid on the pot and leave it to ferment in a cool spot for a few months.

Once November or December have come, you might want to bake your gingerbread cookies.

I take a portion from the dough, put it in a large baking bowl and place the bowl on a water filled pot on my stove for a few hours to get slightly warm so that I can knead in the things I want to knead in.

These will be:

− a pinch of salt

− 2 or 3 or… tablespoons full of „gingerbread spice“

− candied lemon and orange peel

− candied fruit (ginger, cherries, dates…) all cut into small pieces

− ground or chopped almonds, cashew nuts, walnuts etc.

− chopped dark or milk chocolate

− maple syrup

− ground cardamom, cinnamon, pepper, cloves, a little nutmeg, allspice, coriander, ginger (if you cannot buy “mixed gingerbread spice”), ground (organic) vanilla

Once you have mixed your dough with these goodies the next step is to add 2 leavenings. In Germany we use 2 tablespoons of “Hirschhornsalz” (hartshornsalt, ammonium carbonate) dissolved in a little lukewarm milk, stir that into the dough, followed by 2 teaspoons of potash (potassium carbonate), also dissolved in lukewarm milk and stirred in. If these are not available, use 2 tablespoons of baking powder and 2 teaspoons of baking soda.

Add a little more water or – more likely – some organic flour to get the dough to a consistency that enables you to form little balls of dough with a teaspoon and your hand which you then put on a wafer on a baking tray and press it to form a pancake shape. The cookie will rise a bit perhaps by 100% in height and a bit less in width. You’ll find out the right amount of dough for each wafer soon. About the amount of the size of a walnut?

Bake at 180°C/350°F on the lowest shelf for 15 to 18 minutes. Don’t bake your gingerbread too dark – just nice and brown. Cool on a rack with good air circulation.

Then, the next day, you can proceed if you wish and add the icing / chocolate coating.

My favourite is a gingercake with lots of candied orange and lemon peel, candied ginger, walnuts, sliced dates, cashewnuts, chopped chocolate, covered in a chocolate coating of molten chocolate which we call “couverture” with a French word.

But I also like this icing:

250 grams/1/2 pound powdered suger

1 or 2 tablespoons of organic lemon juice

4 or 5 tablespoons of raspberry (or other red) juice

2 handfuls of dried red rose petals

In a mixing bowl mix the lemon juice, raspberry juice and dried red rose petals.

Use an immersion blender to cut the petals into very fine pieces in the juice, which can take about 3 to 4 minutes.

Add the powdered sugar until you get a thick icing which you can use to “paint” your cookies. The raspberry juice makes the mixture a pastel pink, in which the darker red rose petal pieces give you nice red dots – and the lemon juice the much needed zing.

Kept in airtight containers (metal boxes, jars…) the gingerbread cookies would keep until Easter. ; – )

If they should get a bit hard, put half a small fresh apple into the container, which will give them some moisture back.